- Executive summary

- The rise of construction automation

- How automation benefits construction

- From autonomous robotic diggers to electric-powered haul trucks

- A “new Industrial Revolution?”

- Fuelled by labour shortages

- The future of construction automation

- Learnings

Executive summary:

The once-familiar sight of construction workers operating heavy machinery is slowly giving way to a new breed of workers: autonomous machines. From self-driving bulldozers that can grade terrain with millimetre precision to robotic bricklayers that can construct walls faster than humans, these machines are demonstrating their worth across a range of applications.

- Built Robotics has developed an autonomous excavator that uses computer vision, machine learning, and advanced sensors to conduct digging operations.

- Researchers from ETH Zurich have developed an autonomous machine that can quickly construct dry-stone walls.

- 81% of construction companies plan to implement construction automation within the next decade.

- 68% of construction firms are struggling to fill open positions due to a lack of available qualified candidates.

- The first Industrial Revolution was more than 100 years ago, and we are absolutely at the beginning of a new Industrial Revolution centred around robotics and artificial intelligence”, says Jeremy Searock, co-founder of Advanced Construction Robotics.

It appears certain that automation will have a meaningful role to play in tomorrow’s construction industry. But just how big of a role—could we soon see construction sites devoid of human workers? Or will the industry always rely on a symbiotic relationship between man and machine?

The rise of construction automation

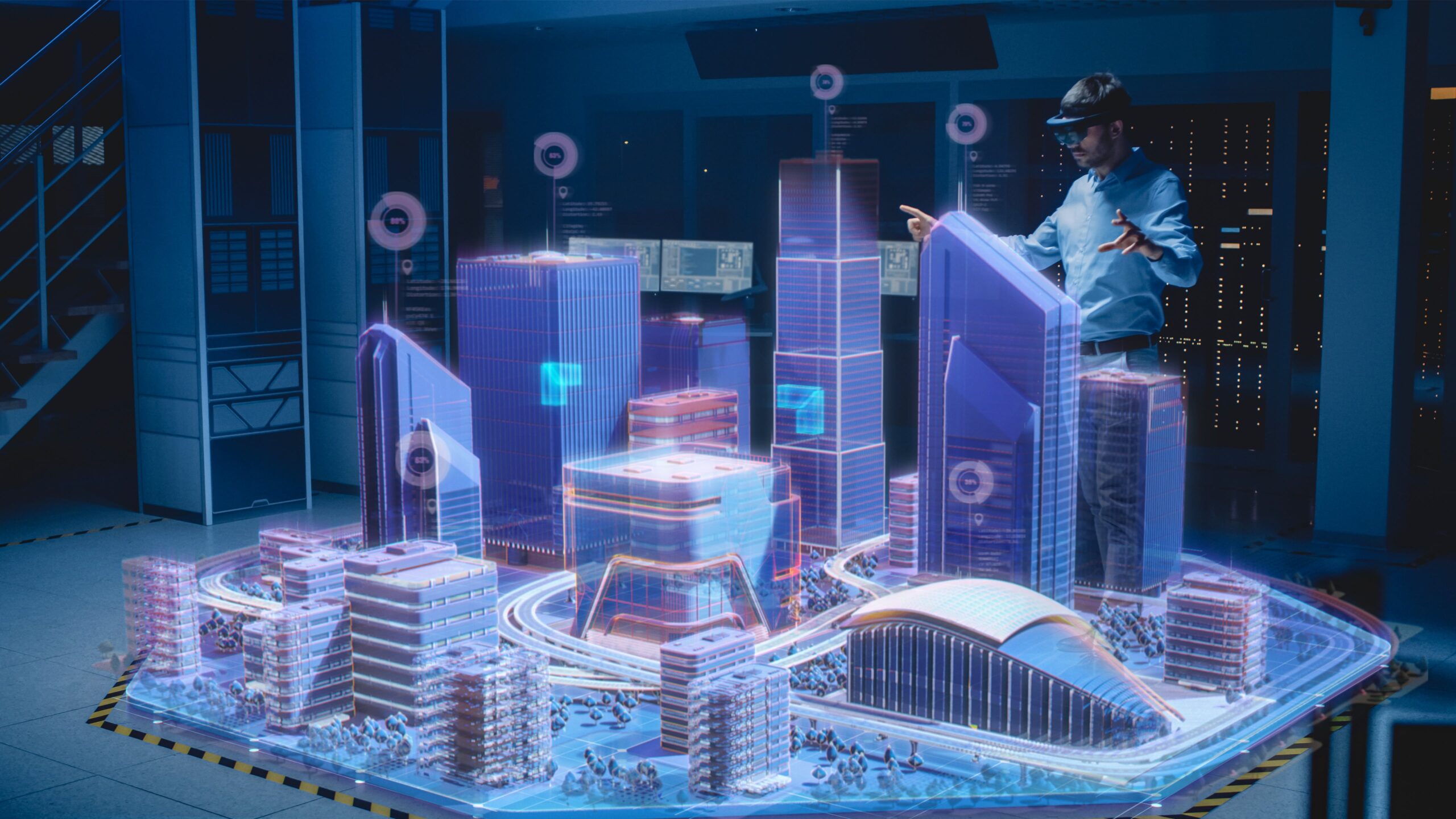

A quiet but powerful shift is underway in the construction industry. The once-familiar sight of human operators handling heavy machinery is slowly giving way to a new breed of workers: autonomous machines. These sophisticated entities, equipped with sensors, cameras, and intelligent software, are proving to be more than a mere novelty. Rather, they are becoming an integral part of the construction process.

The emergence of autonomous construction machinery is not some sudden development. It results from years of research and development to improve efficiency, safety, and precision on construction sites. From self-driving bulldozers that can grade terrain with millimetre precision to robotic bricklayers capable of constructing walls faster than their human counterparts, these machines are demonstrating their worth across a range of applications.

The construction industry is facing increasing pressure to build more with fewer financial resources, making the adoption of autonomous machinery an attractive solution. These machines can significantly reduce the need for human labour in hazardous or repetitive tasks, thus improving safety and enabling construction firms to optimise their workforce, focusing human talent on tasks that require critical thinking and creativity.

“The first Industrial Revolution was more than 100 years ago, and we are absolutely at the beginning of a new Industrial Revolution centred around robotics and artificial intelligence”.

Jeremy Searock, co-founder of Advanced Construction Robotics

How automation benefits construction

Automation brings a wide range of benefits to the construction industry, including improved productivity and safety, reduced waste, and decreased environmental impact.

While it may seem like a relatively recent development, the idea of mechanised automated construction is actually several centuries old. Its origins can be traced back to the late 200s BCE, when the first Chinese emperor, Qin Shi Huang, used prefabrication techniques to build his Terracotta Army. However, it wasn’t until the invention of the first industrial robots in the 1950s that automation as we understand it today came into being. The automotive industry was the first to embrace the trend, with construction following suit in the 1960s and 1970s.

In the 1970s and 1980s, automated construction took a giant leap forward with the development of robots and remote-controlled machines for a wide range of construction tasks. The drivers of change were often Japanese companies like Shimizu Corporation, Obayashi Corporation, and Takenaka Corporation. Japan was experiencing a severe shortage of construction labour at the time as a result of an ageing population and disinterest among younger generations. In response to these issues, the country invested heavily in research and development, creating innovative automated solutions to address the labour crisis and keep the sector going.

Automation in construction can take many forms, the most straightforward of which is physical, on-site work like excavating, laying bricks, and placing rebar. However, off-site construction automation is gaining momentum, involving the production of modular building components in factories via modern techniques like 3D printing. It is also possible to automate design, planning, and management processes through the use of digital tools and platforms like Building Information Modeling (BIM). In this article, we will focus primarily on physical on-site work and the ways in which companies can implement it.

There are no shortage of ways in which automation can benefit construction companies. At the most basic level, it improves productivity and reduces the amount of time required to complete projects. However, it can also help construction companies better utilise their resources and minimise waste, which in turn can help reduce the industry’s environmental impact. In addition to making workers more productive, automation can help keep them safe on-site by reducing their exposure to hazardous tasks and environments.

From autonomous robotic diggers to electric-powered haul trucks

There is a growing number of automated machines that can perform a wide range of construction tasks.

One of the most noteworthy recent developments in automated construction comes from tech firm Built Robotics, which has developed an autonomous excavator that leverages computer vision, machine learning, and advanced sensors to conduct digging operations with superlative accuracy and consistency. The excavator is equipped with a sophisticated ‘Exosystem’ that allows it to navigate the job site, avoid obstacles, and complete tasks with minimal human intervention. However, we can also see the nascency of the technology in this excavator: it can only dig trenches in straight lines and remains reliant on human operators to set up the work area, define the parameters of the job, and supervise the process. It also cannot make complex decisions or adapt to unexpected changes in the environment.

In terms of actual building, we have HEAP (Hydraulic Excavator for an Autonomous Purpose), an autonomous machine designed to construct dry-stone walls. Developed by a team from the ETH Zurich research institute, HEAP uses a combination of LiDAR sensors, machine vision technology, and advanced algorithms to scan a construction site, create a detailed 3D map of the area, and locate the boulders that will be used to build the wall. It then carefully lifts each boulder, weighing and analysing its shape and centre of gravity before determining its optimal placement. Across several building sessions, HEAP was able to construct a dry-stone wall six metres high and 65 metres in length, placing between 20 to 30 boulders—each of which can weigh several tonnes—per session.

In a groundbreaking collaboration, SafeAI, a Santa Clara-based company specialising in autonomous heavy equipment retrofitting, has teamed up with Japanese construction giant Obayashi Corporation to introduce a one-of-a-kind haul truck that combines driverless operation with battery-electric power. Rather than building the vehicle from the ground up, the companies retrofitted an existing Caterpillar 725 haul truck with SafeAI’s autonomous software, enabling it to perceive its environment and respond to changing conditions in real time. The result is a piece of equipment that promises improved safety, increased efficiency, and demonstrably better sustainability. According to SafeAI, the combination of autonomy and electrification can increase productivity by about 20%.

“A talented operator might be fast for a few hours. But if you’re doing it over the course of a longer period of time, you’re going to find the automated process will likely perform better.”

Scott Crozier, general manager of Trimble

A “new Industrial Revolution?”

Industry experts largely agree that autonomous machines will significantly improve productivity, quality, and safety in construction.

For the most part, experts agree that autonomous machines will have a significant impact on the construction industry—especially in terms of productivity, quality, and safety. “The first Industrial Revolution was more than 100 years ago, and we are absolutely at the beginning of a new Industrial Revolution centred around robotics and artificial intelligence”, says Jeremy Searock, co-founder of robotic equipment provider Advanced Construction Robotics. However, not every piece of construction equipment can currently be automated. With some machines, such as compactors or mining trucks, it is easy to do because their operation is relatively simple.

“When it comes to construction equipment, there is such a spectrum”, explains Chris Sleight, managing director of management consultancy Off-Highway Research. “There are examples of where autonomous equipment is already working in mining, where it is more of a closed loop. Gradually it is spreading down to smaller mines and quarries. The next area where it could potentially be applied to is new-build infrastructure projects where you already have the highest degree of machine control now, in machines like dozers, graders, and pavers”. However, with more complex machines and tasks that involve work in more unpredictable environments, automation may not always be feasible. “Every site will be different and you won’t necessarily have a plan you can impose on your machines. It’s hard to see where the economic argument would come in for a small, complex, confined site”, adds Sleight.

Scott Crozier, general manager of industrial technology company Trimble, believes that autonomous equipment will enable construction companies to significantly improve their efficiency. “A talented operator might be fast for a few hours”, he says. “But if you’re doing it over the course of a longer period of time, you’re going to find the automated process will likely perform better”. However, that doesn’t mean that human workers will no longer be needed on construction sites. “With labour in short supply, the only option is to make a single person more productive, and that’s what robots do”, adds Searock. “By working with a robot, one person can do the work of an entire crew. The goal is not to reduce headcount, but to give each person on the job the opportunity to perform higher value tasks”.

What does this mean for tomorrow’s construction workers? Many will need to upgrade their skills and become more digitally savvy if they want to be able to handle this high-tech equipment. “Digital literacy has to come up”, explains Aidan Maguire, business unit manager for measuring and robotics at manufacturing company Hilti. “We’ll see it naturally with this new generation. But the new generation can’t throw away the knowledge and best practices of the past because those core skills are required to use any technology effectively. We have to figure out the best way for contractors to marry those two worlds together”. Perhaps most importantly, increased adoption of automation will make the industry more attractive to younger generations, which will go a long way towards addressing the existing labour shortages. “Your experienced operators are never going to go away”, says Finlay Wood, business area director for autonomous solutions at Trimble. “But robotics and autonomy are going to make the jobs more accessible to young people”.

“The new generation can’t throw away the knowledge and best practices of the past because those core skills are required to use any technology effectively. We have to figure out the best way for contractors to marry those two worlds together”.

Aidan Maguire, business unit manager for measuring and robotics at Hilti

Fuelled by labour shortages

Studies show that the increased adoption of automation in construction is fuelled primarily by labour shortages.

By now, it’s probably clear that the lack of skilled labour is one of the main driving forces behind the growing interest in automation among construction firms. According to the AGC 2023 Workforce Survey, 68% of firms are struggling to fill open positions due to a lack of available qualified candidates, while workforce shortages have caused project delays for a further 61%.

The industry’s ageing workforce is a compounding factor in this. According to the Associated Builders and Contractors, a trade group based in Washington D.C., about 20% of construction workers are over the age of 55. Troublingly, the industry could lose 41% of its current workforce to retirement by 2031, reveals a 2020 McKinsey report.

One major reason why construction firms have struggled to replace their departing workers with younger talent is their reluctance to embrace new technologies. Fortunately, that may be changing. A 2021 ABB Robotics survey found that 81% of construction companies plan to implement construction automation within the next decade. When asked to share their views on AI and robotics, only 17% expect that automation will have a negative impact on the industry, highlighting the loss of jobs as a potential risk. On the other hand, 44% of respondents in the AGC 2023 Workforce Survey said they believe that they will have a positive impact on construction jobs, primarily by automating manual tasks that are often prone to error.

41% of respondents also indicated that the impact of AI and robotics will be most evident in the improved quality of construction jobs, as well as improved productivity and safety of construction workers. Construction is one of the most dangerous occupations, accounting for nearly 20% of all worker fatalities in the US in 2022, according to the Occupational Safety and Health Administration. It’s no surprise, then, that the autonomous construction equipment market is expected to grow from $15.41 billion in 2024 to $22.31 billion in 2028, according to a 2024 report published by The Business Research Company.

The future of construction automation

The adoption of automation in construction will continue to grow, but fully automated construction sites may be a step too far.

It is widely expected that automation will take on an increasingly prominent role in the construction industry in the upcoming years. The only question is: how far will we be able to push it? Will there come a time when autonomous machines and robots will take over the entire building process, constructing towering skyscrapers and sprawling residential complexes without any human involvement? While this scenario may not be entirely beyond the realm of possibility—especially considering the rapid pace of technological development—the inherent complexity and unpredictability of construction sites pose significant challenges to full automation.

It is more likely that we will see humans working alongside machines, focusing on tasks that require complex problem-solving and in-depth analysis while letting their mechanical counterparts take on the more repetitive and physically demanding tasks. The industry will need to find a way to strike the right balance between human expertise and machine efficiency. The adoption of automation will also enable construction companies to attract and retain a new generation of workers. Millennials and Gen Z-ers, who have grown up with technology at their fingertips, have come to expect the same level of convenience and technical sophistication in their place of work and will be significantly more drawn towards companies that utilise cutting-edge tools and technologies.

Learnings

As the construction industry continues to evolve, the integration of autonomous machinery is becoming increasingly crucial. Innovations like autonomous excavators, robotics bricklayers, and self-driving haul trucks are becoming a common sight in construction sites around the world.

- There are clear benefits to autonomous construction technology, including improved safety, increased efficiency, and reduced environmental impact.

- Construction is one of the most dangerous occupations, accounting for nearly 20% of all worker fatalities in the US in 2022.

- 44% of respondents in the AGC 2023 Workforce said they believe that AI and robots will have a positive impact on construction jobs.

- 41% of respondents believe that the adoption of AI and robotics will lead to improved quality of construction jobs, as well as improved productivity and safety of construction workers.

- The autonomous construction equipment market is expected to grow from $15.41 billion in 2024 to $22.31 billion in 2028.

Will the rise of autonomous machinery ultimately lead to a symbiotic relationship between humans and machines, where the unique strengths of each are harnessed to create a more vibrant and sustainable world? Or will it usher in a new era where the very nature of work and the role of human builders are fundamentally redefined?