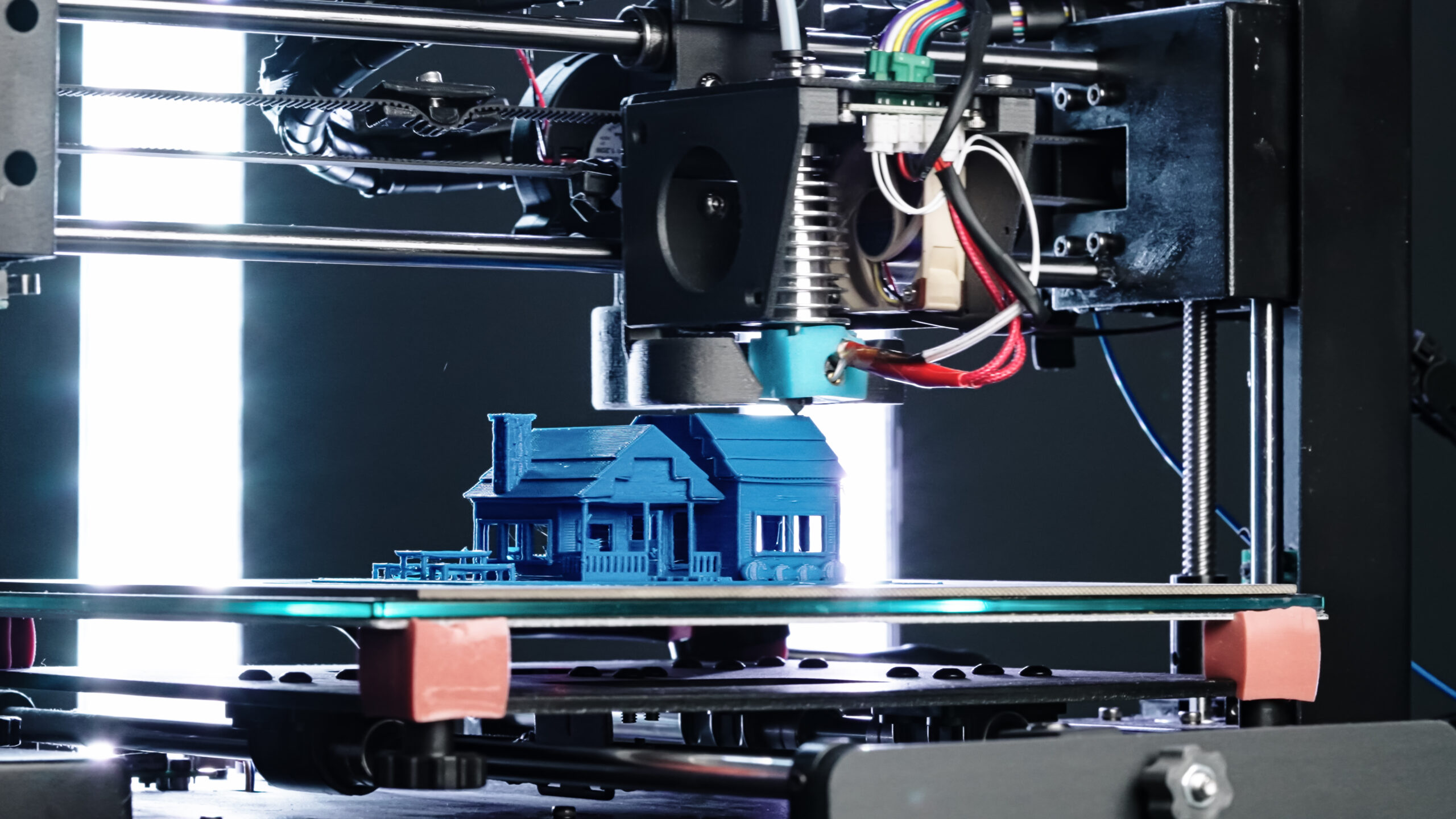

Cutting-edge technologies such as 3D printing and sustainable alternatives to concrete hail the future of construction.

With construction changing as fast as it does, we can expect the sector to become more cutting-edge and cloud-connected. The construction industry has been reluctant to embrace the new for decades, focusing instead on traditional methods to accomplish its goals. However, it was pressured to reduce construction times, growing shortage of workers, repeated demands to minimise the sector’s carbon footprint. To achieve that, the construction industry has started slowly adopting new technologies that show immense potential to upscale construction processes.

The novel Coronavirus pandemic, unfortunately, has caused much damage to all industries, affecting the construction industry as well, which reflects on its reluctance to start using new technologies on a larger scale. For instance, the global 3D printing building construction market is expected to dive to $0.002 billion in 2020, falling at a compound annual growth rate of -35.76 per cent. But the future doesn’t seem bleak as once the wave of lockdowns start to fall and the business world gets back on its feet, we might expect industries to rejuvenate. The list of benefits of using new tech such as 3D printing and other cutting-edge technologies is far too long to even think that construction doesn’t value intelligent solutions and novelties, especially during difficult times such as these.

3D- printing could be a true game-changer for the sector, but the ‘ink’ is a problem

Despite numerous benefits that 3D-printing delivers to the construction industry, not everyone shares the same enthusiasm. This cutting-edge building method is a far superior alternative to conventional building, from being time- and cost-efficient to producing less waste material. Given that cement is said to be the world’s third-largest emitter of carbon dioxide, it’s not an ideal building material. “About 1 kilogram of carbon dioxide is released for every kilogram of cement made today,” noted Yet-Ming Chiang, the Kyocera Professor of Materials Science and Engineering at MIT. According to some estimates, the number of buildings worldwide is set to double in forty years, which is equivalent to “building one new New York City every 30 days,” Chiang underlined. To achieve zero carbon emissions, we must use materials that are more environmentally friendly, and scientists and experts in the field are already working on developing new materials that could contribute to a wider application of additive manufacturing if the ‘ink’ used is eco-friendly.

An eco-friendly ‘ink’ for 3D-printers

A team of scientists at the London-based Novacem managed to develop a sustainable alternative based on magnesium sulphate. The company claims that “each tonne of cement can absorb up to 0.6 tonnes of CO2” compared to traditional cement which emits about 0.4 tonnes of carbon dioxide. Another great alternative could be using the material that’s everywhere and doesn’t need much treatment, soil. Scientists at Texas A&M University have come up with a sustainable 3D printing technology that relies on using local soil as construction material. “Our thought was to turn the clock back and find a way to adapt material from our own backyards as a potential replacement for concrete,” shared Aayushi Bajpayee, a graduate student who was part of the project. They built a ‘toolkit’ that is used to ‘zipp’ microscopic layers on the soil’s surface, thus preventing the absorption of water and material’s expansion. The researchers claim that, treated this way, the material can hold twice as much weight. “We have worked on addressing the problem of building all-weather roads in the subarctic. [The technology] could one day be used beyond Earth, to create settlements on the moon or even Mars,” emphasised Sarbajit Banerjee, the project’s principal investigator. Eco-friendly and innovative building materials such as these could help the sector eventually become carbon neutral.

Intelligent and sustainable homes are all we wished for

In the context of the current epidemic plaguing the world, living in a home that ensures an almost sterile environment might seem like a dream. Haus.me, an American company that builds 3D-printed smart homes, has managed to design and build just that — a perfect home of tomorrow. Small in size, a bit over 37m² sustainable studio home boasts intelligent solutions integrated. “The glass and sleek, white exterior look like a spaceship, with a futuristic fingerprint entry. Every aspect of the home can be controlled through an app, like temperature, humidity, and how much energy is being used,” writes Business Insider. It also comes with an advanced HEPA air quality control and a system that’s able to eliminate as much as 99.9 per cent of bacteria and viruses, which makes the house even more appealing in times such as these.

Additive manufacturing changes the face of the construction sector

3D-printing, combined with other intelligent solutions, can help the construction sector build homes without using concrete that harms the environment. Sustainable homes could ensure that our living space protects not only inhabitants, but the environment, too. One 3D-printed object at a time, we’ll be soon living in sustainable and affordable homes.