- How AI can streamline bridge maintenance

- Using technology to monitor the structural health of civil infrastructure

- Enhancing construction training with mixed reality

Digital technology has taken on an increasingly prominent role in various aspects of our lives in recent years, transforming one industry after another in the process. Although it has traditionally been highly resistant to change, the construction industry is now also becoming more open to new technologies, recognising the myriad of benefits they bring to the table. This is particularly true when it comes to the inspection of physical infrastructure, an area that has historically been dominated by manual processes and reliant almost exclusively on human expertise, making it not only labour-intensive but time-consuming and very expensive as well. However, this is now starting to change, and these traditional methods are being gradually phased out in favour of more forward-looking ones. Instead of relying on reactive measures and after-the-fact assessments, the industry is increasingly moving towards a more proactive approach, where potential issues are identified and addressed long before they turn into major problems.

This ongoing transformation of the inspection process is fuelled in large part by the growing adoption of innovative technologies like artificial intelligence, augmented and virtual reality, drones, and the Internet of Things (IoT). The benefits of integrating these technologies into the inspection process are manifold. For one, the accuracy of data collected is significantly improved, leading to more precise assessments. Furthermore, inspection times are dramatically reduced, which in turn enhances operational efficiency. The safety of personnel is also greatly enhanced by minimising human involvement in potentially hazardous situations. But most importantly, by leveraging real-time data and predictive analytics, inspectors can identify potential issues early on, allowing for swift, preemptive action. This not only reduces repair costs but also extends the lifespan of buildings. In the following chapters, we are going to take a closer look at some of the latest innovations that are set to redefine the way we conduct building inspections.

There are more than 600,000 bridges in the US alone, each of which needs to be inspected every two years. This translates to more than 300,000 bridge inspections per year.

How AI can streamline bridge maintenance

Bridges serve a pivotal role in our everyday lives. Without them, many regions would remain cut off from the rest of the world by physical obstacles like rivers and canyons, limiting their opportunities for growth. The presence of bridges mitigates these limitations, as they establish a vital link between regions and enhance the efficiency and continuity of our transportation networks. These structures facilitate the movement and exchange of people, goods, and ideas, thereby promoting cultural and economic growth. However, while bridges are built to last — and do indeed stand firm for a very long time — they are not immune to the ravages of time. As years go by, the durability, function, and structural safety of bridges inevitably degrade, causing them to suffer damage. If the damage is not repaired in a reasonable time, they may even collapse entirely. Reinforced concrete is widely considered to be the biggest culprit in this degradation, due to a phenomenon known as concrete carbonation. Over time, various substances from the environment — like carbon dioxide and seawater — infiltrate the concrete and trigger chemical reactions with other substances contained within. This results in the corrosion of the embedded steel reinforcements, which, in turn, causes cracks in the concrete. Repairing these cracks can be a very expensive and time-consuming process, which is why the industry has been looking for ways to track the deterioration over time and react before it affects the safety of the bridge.

There are more than 600,000 bridges in the US alone, each of which needs to be inspected every two years. This translates to more than 300,000 bridge inspections per year, a very costly and time-consuming task, especially if performed manually, which has been the case until now. But recently, a team of researchers from South Dakota State University’s Jerome J. Lohr College of Engineering, led by professors Mostafa Tazarv and Kwanghee Won, have developed a set of AI-powered tools called BrDATs. They use computer vision and engineering analyses to automatically assess the safety of a bridge by identifying cracks and other types of damage in the bridge’s major structural components, such as columns. The tools are all contained within a single application, which allows users to determine whether a bridge is safe or not — simply by taking a photo of the structure and uploading it to the app. In fact, the app is so easy to use that even those with no previous engineering experience will be able to understand how it works. “Once a picture is uploaded, the AI software is going to find if there’s any cracking, if there is any spalling, if there is any bar exposed”, explains Tazarv. “There it will tell if the bridge is safe or not. The user of the bridge assessment tool doesn’t need AI knowledge, and you don’t need to be a structural engineer. We made an app where everything is being done behind the scenes for you”. This could help save a great deal of time and money, forever changing the way we conduct bridge inspections.

“Structural health monitoring is an area of need internationally. It’s almost like human health monitoring. As we get older, monitoring our health becomes very, very critical”.

Necati Catbas, a professor in UCF’s Department of Civil, Environmental and Construction Engineering

Using technology to monitor the structural health of civil infrastructure

Of course, it’s not just bridges that require constant maintenance; the same applies to other types of civil infrastructure as well, such as roads or buildings. All of these structures degrade over time and their structural health needs to be monitored to ensure the safety of the people that use them. To streamline this process, a team of researchers from the University of Central Florida have developed several innovations that use artificial intelligence and virtual reality technologies to help inspectors monitor the structural health of civil infrastructure. “Structural health monitoring is an area of need internationally”, says Necati Catbas, a professor in UCF’s Department of Civil, Environmental and Construction Engineering. “It’s almost like human health monitoring. As we get older, monitoring our health becomes very, very critical”. The first of these tools is the Comprehensive Structural Health Monitoring System, which uses cameras that are strategically positioned around the structure to capture a wide range of data related to its use. The collected data is then processed and analysed by the computer vision software to determine whether the structure is still safe to use. In addition to highlighting any damage that requires immediate attention, the assessment also provides information about structural changes and weaknesses. “We can use the camera, and by analysing the images, we can extract meaningful information about these bridges and buildings”, explains Catbas.

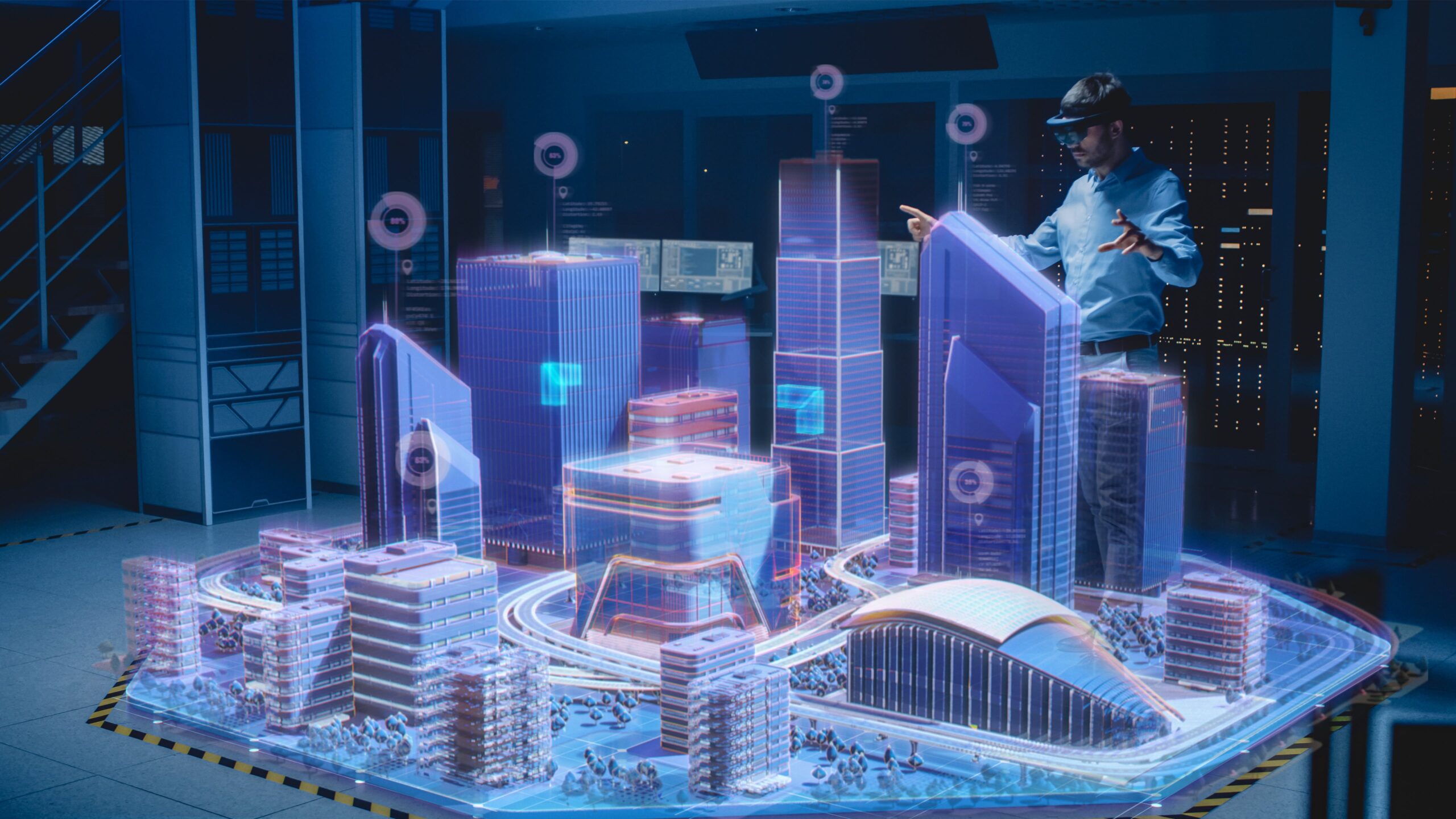

The team also developed the Immersive Visualisation System, which allows inspectors to check a structure in a computer-simulated environment and accurately assess its load-carrying ability and identify signs of damage. The system uses a wide range of cutting-edge technologies, including sensors, robots, drones, LiDAR scanners, and infrared thermography cameras, to collect the necessary information about the structure and faithfully recreate it in a virtual environment. “With this technology, you can virtually bring experts to disaster areas, such as buildings and bridges, like after a hurricane”, adds Catbas. “I can virtually be on a damaged bridge in Florida discussing decisions with colleagues who might be in California”. Both of these innovations eliminate the need for inspectors to be physically present at the location, significantly increasing the efficiency of the inspection process. The third innovation is the Collective Intelligence Framework, which aims to accelerate the inspection process through a combination of AI and mixed reality technologies. It requires an inspector to first put on a headset and use the accompanying handheld device to scan the damaged structure. Then, the system analyses the structure’s condition in real time and overlays the information onto the inspector’s field of view. The system also allows the inspector to zoom in and inspect potentially dangerous or hard-to-reach sections of the structure from a distance, enhancing their safety.

Enhancing construction training with mixed reality

Mixed reality technology can also help enhance the efficiency of construction training. The AR/VR development company VeeRuby Technologies recently unveiled a new MR training application called Construction Inspection, which is designed to train construction industry employees how to inspect buildings for fire safety and other safety mechanisms. The app allows users to import structural plans of their buildings, which can then be overlaid on top of real-world environments to check for any discrepancies. If the user detects that any part of the structure deviates from the original plan, they can instantly generate a report detailing their findings. This allows them to keep track of the construction progress with a high degree of accuracy and easily identify areas that require urgent attention, making the inspection process more efficient and saving the company a great deal of time, money, and resources. All of the 3D models, animations, and designs within the application are created using tools like Maya and Blender, which allow for the creation of high-quality digital content. The application is also compatible with a wide range of operating systems, platforms, and devices, ensuring that it can be accessed and used by as many people as possible.

Closing thoughts

The way we conduct the inspection of physical infrastructure is undergoing a major transformation, driven in large part by the growing adoption of innovative technologies like artificial intelligence, augmented and virtual reality, drones, and the Internet of Things (IoT). These technologies promise to bring a wide range of benefits to the inspection process, significantly improving data accuracy, reducing inspection times, and minimising human exposure to hazardous environments. Perhaps most importantly, they facilitate a switch from a reactive to a proactive approach to maintenance, allowing us to identify and address potential issues before they escalate to something more serious. This preventative strategy has the potential to avert failures, save costs, and extend the lifespan of our infrastructure. As we continue to innovate and integrate technology into this aspect of construction, we are set to not only redefine the way we conduct inspections, but also reshape the industry at large.