- EVE the robot can do your household chores for you

- Agility’s new warehouse robot responds to commands in natural language

- Sanctuary AI’s Phoenix robot: a solution to the world’s labour challenges?

- The SSi Mantra robotic surgeon executes complex heart surgery

Not too long ago, the very idea of robots mingling with humans in everyday life was relegated to the pages of pulp novels and the silver screen. But today, these technological marvels have gradually become an unassuming yet inescapable presence in our midst. Modern robots are a far cry from the bulky, limited machines of the past. They now quietly inhabit spaces that were once the exclusive domain of human hands and minds: assisting doctors in surgery with a precision that surpasses the human hand, tirelessly piecing together cars with unfailing speed, and even dipping brushes into paint to create artwork that challenges our perception of creativity. This article seeks to explore the profound impact of robots on our society. We will consider their pervasive influence in various sectors, how they are changing the nature of work, and the myriad ways in which they are shaping the foundations of our future.

“We’ve all heard for years that robots will soon come to work for us, but it’s never actually happened until now”.

Hege Nikolaisen, head of communications at 1X

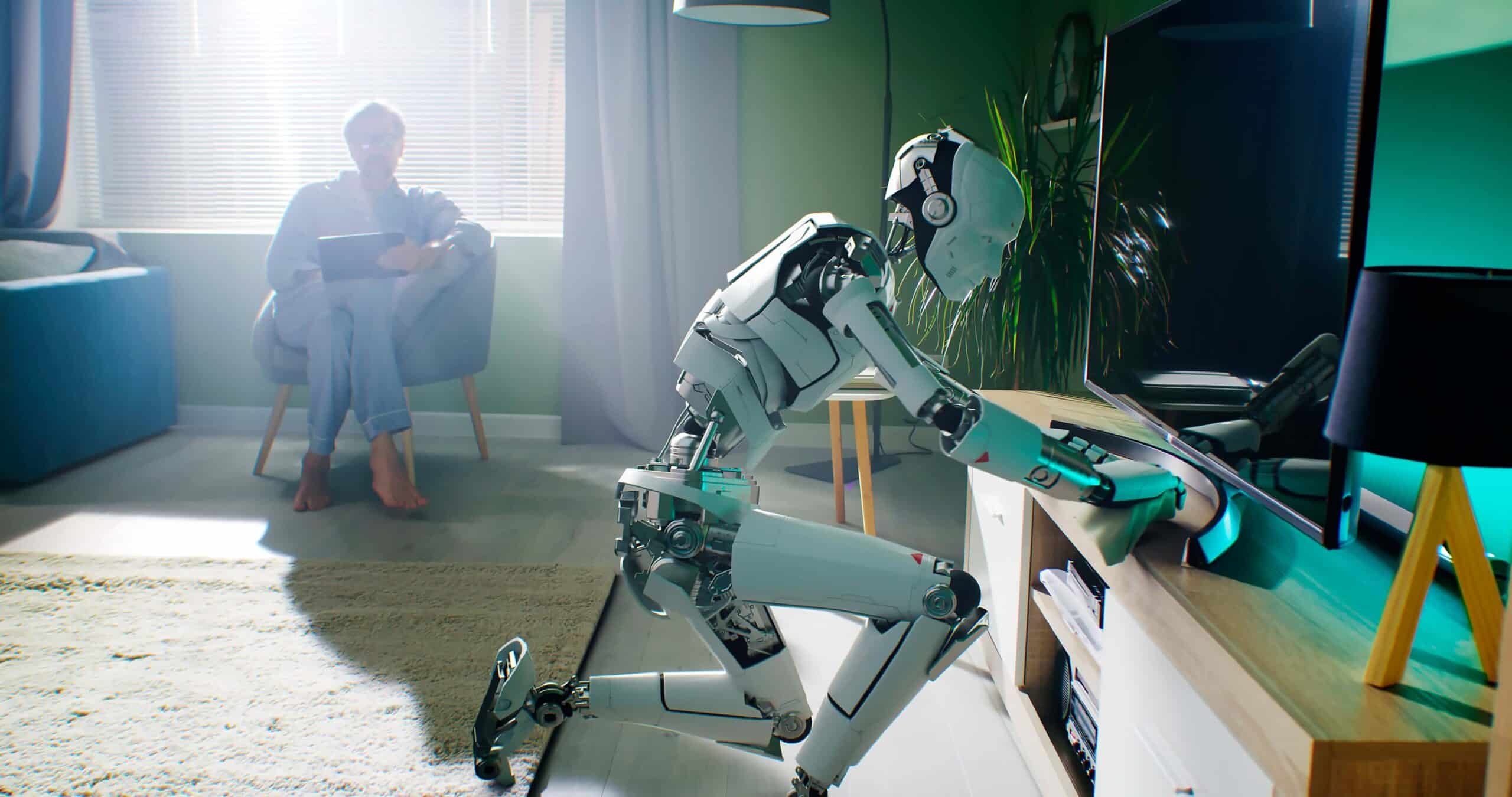

1. EVE the robot can do your household chores for you

It’s probably safe to say that nobody really enjoys doing household chores. They are exhausting and time consuming, and there are frankly so many better, more rewarding things you could be doing with your time. Nevertheless, it’s something that needs to be done. But what if you could get someone or something else to do it for you — say, a robot? Well, that may not be too far in the future as you might think. The Norwegian robotics company 1X recently unveiled a new humanoid robot named EVE, which is capable of handling a wide range of household tasks, and much more besides. Nearly 190 centimetres tall and weighing close to 90 kilograms, EVE is equipped with cameras and sensors that allow it to ‘see’ its surroundings and interact with the objects and people within it. It can move at a speed of up to 14 kilometres per hour and carry around 15 kilograms of weight. The power is provided by a battery that takes about one hour to charge and enables the robot to operate for up to 6 hours.

EVE also has a set of wheels attached to its base. Combined with the cameras and sensors mentioned above, these allow it to navigate even complex environments with ease, while gripper hands enable it to manipulate various objects. However, none of these things are what makes EVE stand out from other robots available on the market. What does set it apart is the integration of a modified version of GPT-4, which enables it to accomplish some pretty remarkable things. For example, it can scan your fridge and kitchen shelves and suggest creative recipes based on the available ingredients. It can even prepare the meal for you if you don’t feel like cooking yourself. Besides cooking, the robot can also help with cleaning, shopping, tutoring, and even guarding your home. But that’s not all it can do.

EVE also excels in environments that extend beyond the home. It can, for instance, handle various production, assembly, quality control, and maintenance tasks in factories, as well as logistics tasks in manufacturing. It can also perform guard duties in various buildings or greet visitors and guide them around the premises — all thanks to its natural language capabilities. While EVE is designed to operate autonomously, it can turn the control over to a human operator if it encounters an issue it cannot resolve on its own. “The big barrier in robotics that 1X has managed to solve is creating technology and hardware that is safe enough to be taken out of the factory”, says Hege Nikolaisen, head of communications at 1X. “We’ve all heard for years that robots will soon come to work for us, but it’s never actually happened until now. This is because our androids use strong but energy-efficient motors so that they can safely interact with their surroundings”.

2. Agility’s new warehouse robot responds to commands in natural language

Another area where robots have proven increasingly useful in recent years is warehouse work. Over the course of a typical workday, a warehouse worker is required to execute a number of repetitive tasks, which can often result in injury. This, in turn, leads to a high employee turnover rate and severe staff shortages, which threaten to affect the functioning of our supply chains. Many companies have tried to close the gaps in their workforce by embracing automation. While this has been successful to a certain extent, the biggest problem is that the majority of existing automation solutions are single-purpose, which means that they can only perform a single task. So if there are multiple tasks a company wants to automate, it needs to implement a different solution for each one, which can be rather costly. To address this issue, the US-based robotics company Agility Robotics recently presented an updated version of its warehouse robot called Digit.

Described by the company as ‘the first human-centric, multi-purpose robot made for logistics work’, Digit is roughly the same size and shape as a human and is designed specifically to work in spaces typically occupied by humans. The robot is capable of performing a wide range of warehouse tasks and can easily switch from one application to another. Perhaps most importantly, it doesn’t require any retrofitting, so it integrates seamlessly into existing warehouse operations. “Supply chains are still feeling the aftereffects of the pandemic, and the demand for warehouse labour far exceeds available talent. Companies are turning to automation now more than ever to help mitigate future disruptions. With logistics labour issues such as high turnover, burnout, and injury continuing to rise, we believe Digit to be the future of work”, says Damion Shelton, co-founder and CEO of Agility Robotics. “We look forward to Digit augmenting workforces, taking on the ‘dull, dirty, and dangerous’ tasks, and allowing people to focus on more creative and complex work. We like to think of Digit as enabling humans to be more human”.

Compared to its predecessor, the new version of Digit now has a head and a set of LED eyes to improve its interactions with its human coworkers. It has also been equipped with newly designed hands that allow it to reach higher and carry more weight than the previous version. The robot can easily identify obstacles that may appear in its way and navigate around them. Uneven surfaces don’t pose a problem for the robot either. In fact, it can handle them without having to drop the object it’s carrying. But the most impressive new feature is the addition of artificial intelligence. A demo video recently shared by the company shows Digit executing a complex task on its own without being given detailed instructions. After receiving a command in the natural language, the robot uses a large language model to interpret the request and then proceeds with its execution without a hitch. “We created a demo space with a series of numbered towers of several heights, as well as three boxes with multiple defining characteristics”, explains Pras Velagapudi, vice president of innovation and chief architect at Agility Robotics. “Digit was given information about this environment but was not given any specific information about its tasks. Just natural language commands of varying complexity to see if it could execute them”.

3. Sanctuary AI’s Phoenix robot: a solution to the world’s labour challenges?

Overall, it appears that the development of humanoid robots has really picked up pace lately. Another company making waves in this field is the Vancouver-based Sanctuary AI, which recently introduced the sixth generation of its general-purpose robot named Phoenix. The robot is 170 centimetres tall and weighs 70 kilograms. It can reach speeds of up to 5 kilometres per hour, while its maximum carry capacity is 25 kilograms. Described by the company as ‘the world’s first general-purpose robot equipped with human-like intelligence’, Phoenix is powered by a cutting-edge AI control system called Carbon, which enables it to perform a wide range of tasks with a dexterity comparable to that of a human. “We designed Phoenix to be the most sensor-rich and physically capable humanoid ever built, and to enable Carbon’s rapidly growing intelligence to perform the broadest set of work tasks possible”, says Geordie Rose, the co-founder and CEO of Sanctuary AI. “We see a future where general-purpose robots are as ubiquitous as cars, helping people to do work that needs doing, in cases where there simply aren’t enough people to do that work”.

According to the company, Phoenix is currently capable of performing hundreds of tasks in more than a dozen industries, which could go a long way towards addressing the growing labour challenges facing our society. “To be general-purpose, a robot needs to be able to do nearly any kind of task, the way you’d expect a person to, in the environment where the work is”, adds Rose. “While it is easy to get fixated on the physical aspects of a robot, our view is that the robot is just a tool for the real star of the show, which in our case is our proprietary AI control system, the robot’s Carbon-based mind”. Sanctuary AI recently marked a major milestone in the robot’s development by successfully completing its first deployment in a commercial facility. Over the course of one week, the robot performed 110 retail-related tasks in a real-life environment: a Mark’s retail store in Langley, Canada. The tasks in question were typically those that are either boring or unpleasant for human workers, such as picking and packing merchandise, labelling, tagging, and cleaning, all of which the robot was able to execute correctly.

“Robot surgeries allow surgeons to do complex operations through literally fingertip-sized holes. Patients suffer less trauma, fewer complications, less blood loss, and because of the small size of the incision, they recover very fast and go home in two or three days”.

Sudhir Prem Srivastava, the founder of SS Innovations

4. The SSi Mantra robotic surgeon executes complex heart surgery

This next robot may not be a humanoid, but it’s no less impressive — it can do surgery. While the use of robotics technology in medical procedures is not anything new — in fact, it has been around in some form since the 1980s — it wasn’t until the development of the da Vinci Surgical System that developments in robotic-assisted surgery really took off. Approved by the FDA in 2000, the da Vinci system was designed to facilitate complex surgery using a minimally invasive approach, and it is controlled by a surgeon from a console. This system has become the most widely known and used robotic system for a variety of surgical procedures across the world. To this day, it has been used to perform more than 10 million surgeries. However, as impressive as da Vinci undoubtedly is, the high cost of acquisition and maintenance typically associated with robotic surgery systems has prevented their widespread adoption, particularly in smaller hospitals. One company that has set out to change this is the India-based SS Innovations (SSI) with its SSI Mantra robotic surgical system, the first of its kind to be made in this country.

According to the company, Mantra can be used to perform more than 40 different types of surgical procedures in a wide range of disciplines, including cardiothoracic, head and neck, gynaecological, and urological surgeries. Most importantly, it can do so at a fraction of the cost of the da Vinci system. “Robot surgeries allow surgeons to do complex operations through literally fingertip-sized holes”, says Sudhir Prem Srivastava, the company’s founder and one of the world’s leading robotic cardiac surgery experts. “Patients suffer less trauma, fewer complications, less blood loss, and because of the small size of the incision, they recover very fast and go home in two or three days. Other approaches of open surgery entail large incisions and longer recovery time”. Mantra features a modular, 3D vision open-console design and offers unmatched ergonomics, making the whole experience more comfortable for the surgeon. It also employs machine learning models to improve the surgeon’s efficiency and make the procedure safer for the patient.

To date, the Mantra system has been used to complete more than 500 successful surgical procedures across India. In one of the most impressive demonstrations of the robot’s capabilities, a team of surgeons at Continental Hospital in Hyderabad recently used Mantra to perform a Left Internal Mammary Artery (LIMA) Takedown surgery on a 35-year-old patient. It’s a very complex procedure that requires the surgeon to take the left internal mammary artery from the chest’s internal wall and use it to bypass blocked coronary arteries. This helps restore blood flow to this particular area of the heart and improves the functioning of the heart muscle. After securing regulatory approval in India, the company has set its sights on the United States and Europe next, where it expects to receive approvals from regulatory bodies in 2024 and 2025, respectively.

Closing thoughts

As these intelligent machines become more integrated into the fabric of our lives, they not only augment our abilities but also raise profound questions about the future of human labour and leisure. The potential for robots to take on not just physically strenuous tasks but also those requiring precision and reliability suggests a significant shift in how we perceive and value different forms of work. With this shift on the horizon, we are prompted to reflect: As robots become our partners in both productivity and creativity, what new roles will humans find to satisfy the need for purpose and fulfilment in the age of automation?